LED Strips have been a wildly popular DIY lighting solution for many applications over the years.

That is why we are so pumped on the newest LED Strip tech – COB Flexible Strip Lighting.

If you have never read our LED Strip Light Guide than you should start over there first as that will cover all the basics of LED Strip lighting in general. If you already are familiar with strip lighting and are excited to learn how COB strips make the world of LED lighting even better than read on!

What is COB?

In the LED world, COB is the abbreviation for Chip on Board, which basically means to package the LED die directly on the circuit board (PCB).

The ‘Chip on Board’ LED used on flexible strip lights is also sometimes called a flip-chip.

Flip chip LEDs are basically a bare bones approach to LED structure.

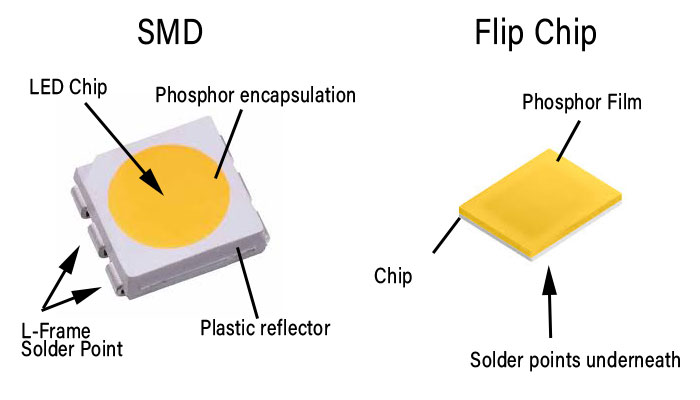

Take a look at the normal 5050 SMD (surface mount device) LED,

it has a bulkier plastic reflector that encapsulates the LED diode itself and then covers that with a phosphor coating.

The ‘flip chipsthat make up COB LED strips cut everything from their design except an LED chip,

the yellow phosphor covering, and connection pads.

This condensed design leads to a significant reduction in size,

allowing them to be packed closer together and further miniaturize LED based lighting.

How are COB LED Flex Strips Made?

The strips are manufactured with the same quality PCB as our other LED Flex Strip lights.

Flip chip LEDs are then placed side by side down the center of the strip light,

so tight that there are 512 LEDs for every Meter of strip!

The strips are finished after a phosphor layer is placed over the LEDs.

This helps balance out the color temperature while also acting as a protective layering for the tiny flip chip LEDs underneath.

Advantages of COB LED Flex Strips

Now that you have a basic understanding of how this new light technology has been produced, it is time to see what makes them superior or better for certain strip light applications.

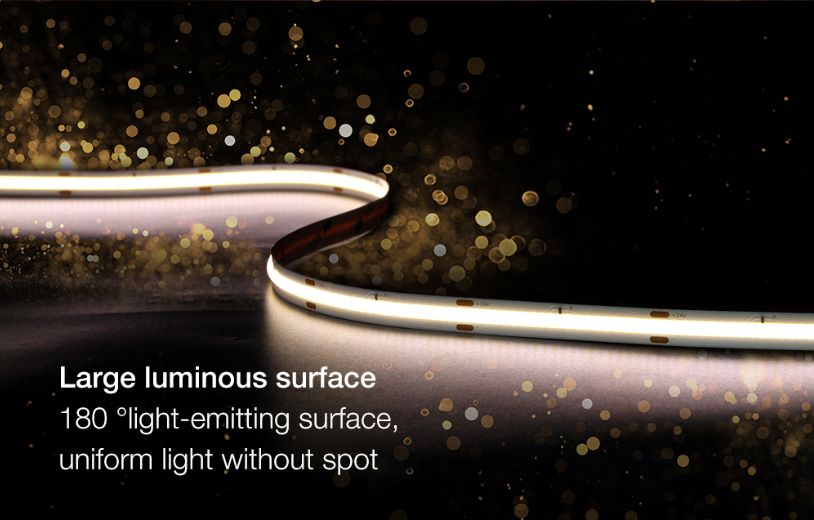

No LED Hotspots, even in tight spaces!

One of the biggest complaints about your traditional LED flex strip is the hotspots throughout the strip.

A Hotspot is the term for the brighter areas through a fixture or strip where you can clearly see where the light is coming from.

Light is much more inviting and attractive when it looks like a smooth source of light,

not a spotty mess.

With 5050 SMD Flex Strips the larger sized diodes are packed close enough so that at a distance the light is spread out and consistent on the surface being illuminated,

but if the lights are too close to the surface or the strips themselves are visible,

the hotspots are an eyesore that cannot be ignored by the human eye.

The strips 512 LEDs/M it would be pretty hard to pick out any hotspots on the COB Flex Strips. The strip illuminates a smooth, consistent light from start to finish. The uniform light has no dark spots and is much more attractive to the human eye, giving off a steady light even in the tightest of places. In fact, the only real way to see hotspots is to look at the back of the strip where it is easier to see the individually placed flip chip LEDs. The only other way you are going to see the individual diodes is if you dim the strips down to about 5% light output. This makes COB Flex Strips ideal for applications where:

1.The strip itself cannot be hidden from sight.

2.The surface that is being illuminated is within 2 feet of the strip light.

3.Reflective surfaces like granite/glass are around.

4.Those applications where you want a cool, neon effect.